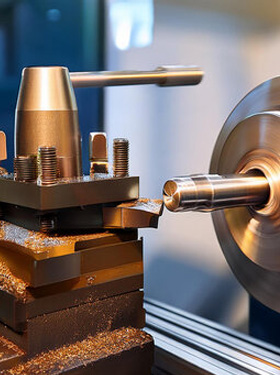

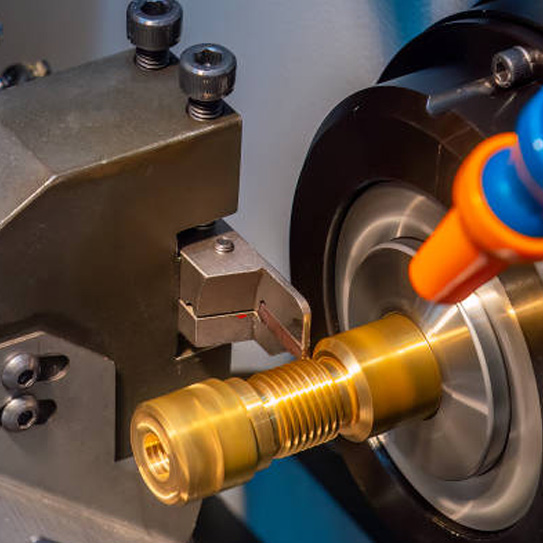

Tilara Manufacturing Company, based in Jamnagar, India - known as the “Brass City of India” - is a trusted manufacturer and exporter of high-precision brass components. With over a decade of industry experience and ISO 9001:2015 certification, we specialize in producing a wide range of brass electrical parts, fittings, fasteners, auto components, and customized precision-turned items.

We serve diverse industries including electrical, automotive, pneumatic, plumbing, and Renewable Energy Sector, delivering solutions that meet global quality standards. Our advanced manufacturing process and quality control ensure dimensional accuracy, superior finish, and reliable performance.

At Tilara Manufacturing Company, we prioritize long-term partnerships by offering competitive pricing, timely delivery, and responsive service. With a commitment to continuous improvement and engineering excellence, we are proud to serve clients across Germany, Spain, the UK, USA, France, Asian countries and many more.

Established a brass foundry, laying the foundation for future growth.

Expanded into brass components trading.

Launched in-house manufacturing of precision brass components.

Doubled production capacity to meet growing customer demand.

Began exporting to European and Asian markets.

Acquired a new 10,000 sq. ft. facility, expanding operations fivefold.

Diversified into multi-metal solutions, adding Aluminum, Copper, Steel, Stainless Steel, and Zinc to our capabilities.

Decades of specialized experience in steel and aluminum engineering components ensuring precision and quality.

Utilization of cutting-edge manufacturing technologies for superior performance and durability.

Rigorous quality control processes guaranteeing reliable, high-grade products every time.

Tailored manufacturing services designed to meet your unique project requirements.

Commitment to on-time delivery without compromising on quality.

Dedicated support and transparent communication throughout the project lifecycle.

Environmentally responsible practices minimizing waste and energy consumption.

Proficient in working with multiple metals including Aluminum, Brass, Copper, Steel, Stainless Steel, Zinc and more to meet a wide range of industrial needs.

Our state-of-the-art facilities and expert team ensure consistent performance in every product

we make.

With a customer-first approach, we aim to build lasting

value across industries we serve.